THE FUTURE OF CONSTRUCTION IS GREEN

FASTER

MORE DURABLE

MORE AFFORDABLE

• No mold, dry rot, termite or vermin

• Fire resistant - Highest industry fire rating

• Magnitude 9.0+ earthquake & category 3 hurricane (200+ mph)

• Reclaimed material and 100% recyclable waste

• Superior noise and heat insulating capabilities

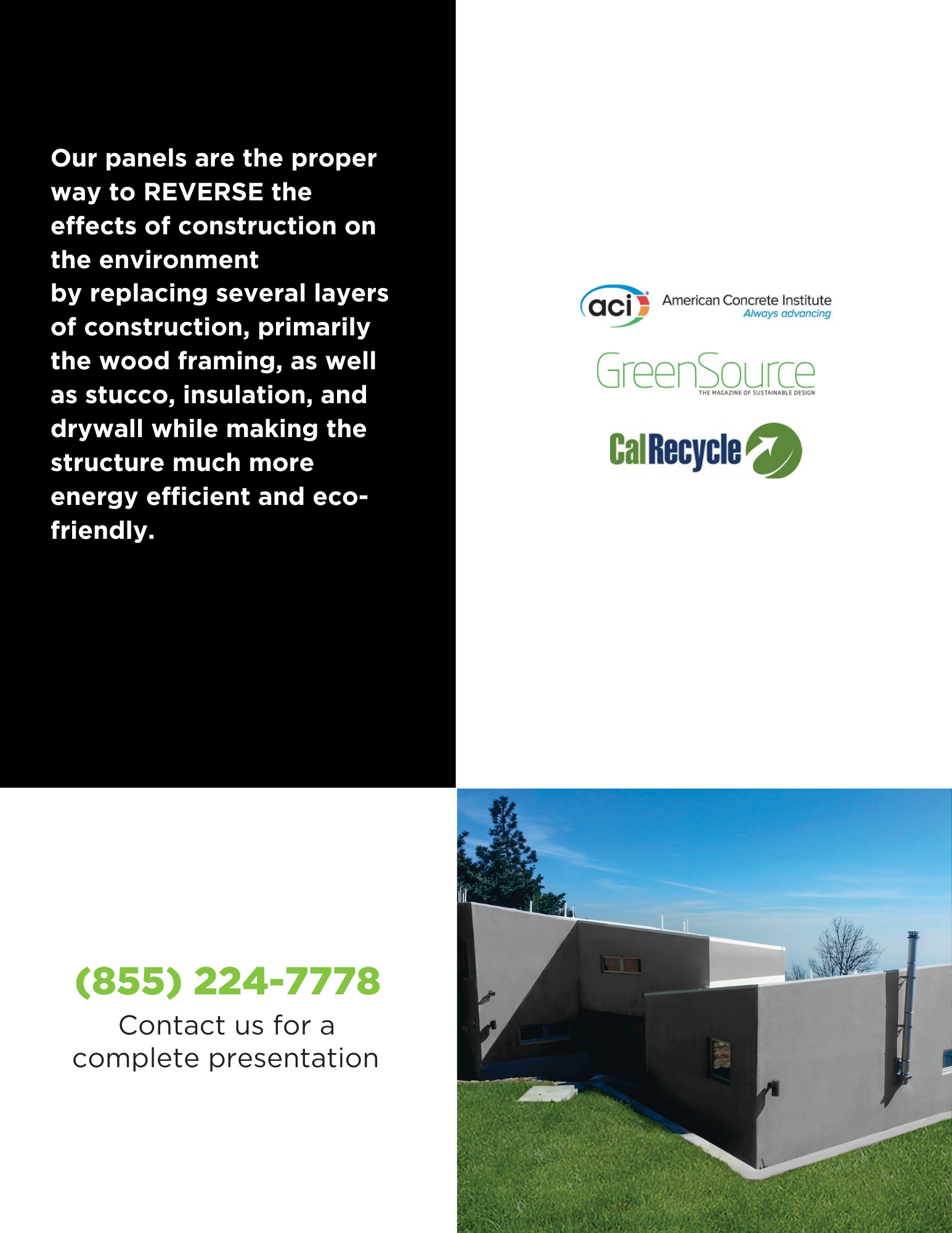

The proper way to REVERSE the effects of construction on the environment

by replacing several layers of construction, primarily the wood framing, as well as stucco, insulation, and drywall while making the structure much more energy efficient and eco-friendly.

FAQs

-

Our panel’s load bearing capacity is in general superior to that of typical wood frame and comparable to bearing capacity of metal frame buildings. A typical 9-foot high and 4- foot panel with 3.0" polystyrene core and 1.125” concrete shell on each side has been tested at a structure load of over 270,000 Ibs.

-

Architects, designers and builders can purchase our panels from our network of certified builders. If you do not know a certified builder in your area call our office at (855)224-7778 and ask for our sales department.

-

Our panels have reinforced concrete skins of a minimum thickness of 1” (25mm), which means that these will have a minimum 90-minute fire rating. In other words, they will resist 1800 degrees Fahrenheit for up to 90 minutes. The concrete skins can be thickened to increase this rating up to four hours.

-

Panels can be waterproofed. The most common methods are either with crystallizing additives in the mix such as Xypex, Kryton, or surface treatments. The surface treatments range from membranes (elastomeric, rubber, etc.) to surface applied materials that result in a change in the concrete to create a waterproof skin.

-

Our panels are designed in conformance with the American Concrete Institute ACI 318 standard. This means that designs employing these panels will comply with just about any building code, IBC, SBCC, BOCA, etc.

-

None of the material in our panels provide food for pests and vermin.

-

Dry-mix pneumatically placed concrete is the preferred method of applying concrete skins to our panels; however, the concrete skins can also be applied by hand, machine plastering techniques, or shotcrete, whether wet-mix or dry-mix (gunite).

-

The "R" system is a method of calculating the resistance of building materials to the transmission of heat. Because our panels are heavier than wood frame and they can store and emit heat, for the same R-Value their performance is superior to that of the wood frame construction. The R-Value of our panels is usually 25+ for walls and 40+ for roofs.